The flow of electricity in a solar cell

The movement of electrons, each carrying a negative charge, toward the front surface of the solar photovoltaic cell creates an imbalance of electrical charge between the cell’s front and back surfaces. This imbalance, in turn, creates a voltage potential like the negative and positive terminals of a battery. Electrical conductors on the cell absorb the electrons. When the conductors are connected in an electrical circuit to an external load, such as a battery, electricity flows through the circuit.

Caspian Pacific Energy Group also deplores thermal generation technology solution harnessing the heat energy released from combustion of hydrocarbon fuel (natural gas) to produce mechanical power. The mechanical power produced is converted to electrical energy with the aid of an alternator for the required electricity.

Our power solution uses a reciprocating spark ignition gas generators to generate power. Our preference for reciprocating gas generator as against gas turbine technology was to allow for flexibility in size or quantum of power to be generated. Where appropriate, we also deploy gas turbine technology.

Our choice of technology is therefore driven by project size with full consideration for investment cost, fuel consumption and medium-term maintenance cost.

We deploy reciprocating power equipment made by Caterpillar (MWM) Energy Solution Gas Generators of Germany, Austria based Jenbacher JGC320GS-NL gas fired technology, the Spanish HIMOINSA gas fired reciprocating engine and other relevant reciprocating engine manufacturers in the United Kingdom, France, China, the United States and other.

These manufacturers are renowned world leaders in manufacturing of gas generators and these gas generators are confirmed and proven technology that can be used in warm, humid and remote location with numerous references and thousands of firing hours.

These Gas engines are lean burn gas generator that complies with TA LUFT standards. The generators are design for high power output, high efficiency, and low NOx emission.

Key Features of Reciprocating Gas Generators

• Easily Scale- able with the ability to generate as low as 1MW of electricity and as high as 50+MW at a single location depending on the requirement.

• Highest efficiency in class.

• State-of-the-art 16-cylinder V-engines with Turbo-charging and two-phase- inter-cooling.

• Total electronic management (TEM) and anti-knock controls for each cylinder

• Optimised engine components

• 50% less lube oil consumption.

• Excellent pedigree – a tradition of many years in engines manufacturing

Thermal Generation Plants Fuel Supply and Logistics

Our thermal generation technology solution plants are powered by Natural gas which are delivered in any or combined of the three stated below.

1. Piped Natural Gas (PNG)

2. Liquefied Natural Gas (LNG)

3. Compressed Natural Gas (CNG)

Thermal Generation Plants Fuel Supply and Logistics

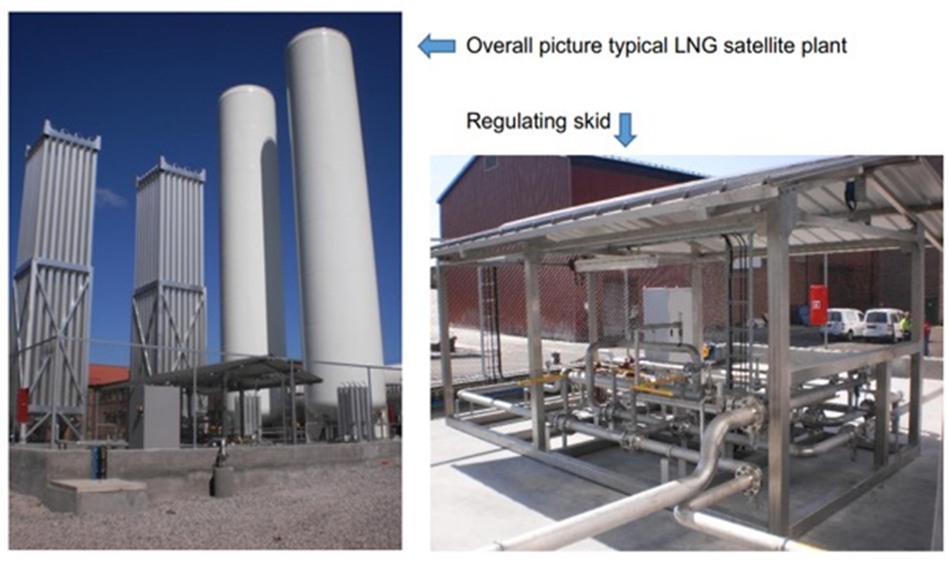

In plants without access to pipelines and far from any downloading station, the primary fuel deployed is natural gas and is supplied in the form of Liquefied Natural Gas (LNG).

Caspian Pacific Energy has developed a robust virtual pipeline strategy to ensure LNG is delivered via cryogenic tanks to all our thermal plants. We install Cryogenic Storage tanks at each project location to receive and store the gas based on the plant’s installed capacity.

Compressed Natural Gas (CNG)

Compressed Natural Gas (CNG) are used for plants with reasonable distance to gas downloading stations.

We design our CNG areas in such a way to accommodate between three to six gas skids depending on the plant’s capacity, to guarantee adequate gas availability. Pressure Reduction and Metering System (PRMS) are also installed, and interconnecting piping connected from the PRMS to respective gas generator.

Natural gas has come of age to become fuel of choice against other high-density liquid fuel. Based on OEM recommendation, the natural gas shall meet the minimum methane number requirement as well as proportional percentage composition.